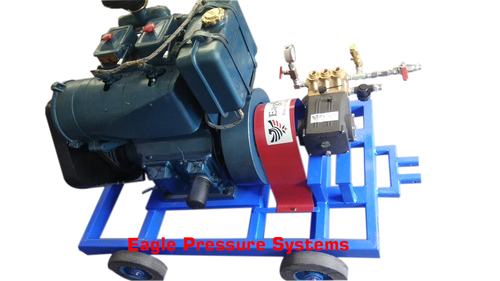

Engine Driven Hydro Test Pump

Product Details:

- Flow Rate 50 LPM

- Theory Other

- Material SS / MS

- Structure Piston Pump

- Power Electric Volt (v)

- Fuel Type Diesel

- Pressure High Pressure

- Click to View more

Engine Driven Hydro Test Pump Price And Quantity

- 225125.00 INR/Unit

- 1 Unit

Engine Driven Hydro Test Pump Product Specifications

- High Pressure

- Electric Volt (v)

- Piston Pump

- Diesel

- Water, Oil Well, Food, Boat, Automobile, Cosmetics

- Other

- Other

- SS / MS

- 50 LPM

Engine Driven Hydro Test Pump Trade Information

- Ahmedabad , Mumbai , Mundra

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 1 Week

- We will do packing of this pump system in standard wooden box.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India, Gujarat, Chhattisgarh, Telangana, Kerala, Goa, Jammu and Kashmir, Daman and Diu, West India, Dadra and Nagar Haveli, Assam, Arunachal Pradesh, Central India, Odisha, Punjab, Madhya Pradesh, East India, Chandigarh, Himachal Pradesh, Bihar, Uttar Pradesh, Andhra Pradesh, Haryana, South India, Delhi, Andaman and Nicobar Islands, Maharashtra, Manipur, Lakshadweep, Tripura, Nagaland, Jharkhand, Karnataka, Uttarakhand, Mizoram, Sikkim, Meghalaya, Rajasthan, Pondicherry, West Bengal, Tamil Nadu, North India

Product Description

Engine Driven Hydro Test Pump

Engine Driven Hydro Test Pump availed by us is especially designed for the testing of the various types of metallic containers such as cylinders, fuel tanks and water pipes. It is provided with a high speed diesel powered compression ignition engine which is directly coupled with impeller to increase the pressure of the fluids. The support frame of this machinery is fabricated by using top quality carbon steel which make it capable to withstand large vibrations and uneven forces.

We are providing Engine driven hydro test pump product

Product Details:

|

Max Flow Rate |

120 LPM |

|

Brand |

Eagle |

|

Usage/Application |

Hydro testing |

|

Pressure |

1000 Bar |

|

Power Source |

Electric OR Diesel OR Petrol |

|

Driven Type |

Direct coupled / Belt pulley driven |

|

Motor Power |

UP to 50 HP |

|

Mounting Option |

Trolley Mounted / Base Frame Mounted |

Product Details :

- Minimum Order Qty : 01 Nos.

- System Brand : Eagle

- Mounting Option : Base Frame Mounted / Trolley Mounted

- Power : 3 Phase , 1450 RPM

- Pressure : UP to 1000 bar

- Flow Rate : Max. 120 LPM

- Power ( HP ) : UP to 50 HP

- Portable : Yes

An Engine Driven Hydro Test Pump is a specialized pump used to perform hydrostatic testing on pipelines, pressure vessels, and other equipment. It is typically powered by an internal combustion engine, which makes it portable and suitable for outdoor or remote locations where electrical power may not be readily available.

Key Features:

-

Power Source:

-

Engine-driven: Typically powered by a diesel or gasoline engine, making it ideal for locations without electrical access.

-

Portable: The engine allows the pump to be moved around to different test sites.

-

-

Hydrostatic Testing:

-

Hydrostatic testing is used to check the integrity of systems that will be exposed to high pressures. The test involves filling the system with water (or another fluid) and pressurizing it to ensure that there are no leaks or weaknesses.

-

-

Pressure Range:

-

Hydro test pumps can generate high pressures, often in the range of 1,000 to 40,000 psi (depending on the application).

-

-

Flow Rate:

-

These pumps usually have adjustable flow rates to allow for different test configurations. For instance, low-flow pumps might be used for small pipelines, while high-flow pumps would be required for large systems.

-

-

Applications:

-

Used in industries such as oil & gas, construction, chemical plants, and manufacturing, where regular testing of pressure systems is necessary.

-

Can be used to test a variety of systems, such as pipes, tanks, valves, boilers, and heat exchangers.

-

-

Safety Features:

-

Many engine-driven hydro test pumps are equipped with safety relief valves, pressure gauges, and emergency shutoff switches to prevent dangerous over-pressurization.

-

Advantages:

-

Portability: Can be taken to any location, including job sites or remote areas.

-

Durability: Built to withstand tough conditions, making them ideal for industrial applications.

-

Efficiency: Provides high pressure with relatively low maintenance.

Disadvantages:

-

Noise: Engine-driven pumps can be noisy compared to electric pumps.

-

Fuel consumption: Since they run on fuel, operating costs can be higher than electric-powered systems.

-

Environmental impact: Engine-driven pumps may produce emissions depending on the type of engine used.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese