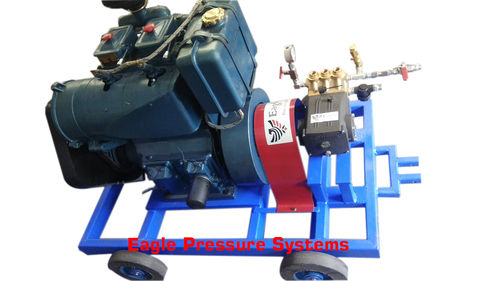

Hydrostatic Test Pump

Product Details:

- Theory Hydrostatic Pressure

- Control System Manual

- Working Temperature 65 Celsius (oC)

- Frequency 50 Hz Hertz (HZ)

- Features Portable, Easy to Operate

- Speed 1440 RPM RPM

- Mounting Type Trolley Mounted

- Click to View more

Hydrostatic Test Pump Price And Quantity

- 101225.0 INR/Unit

- 1 Unit

Hydrostatic Test Pump Product Specifications

- Mild Steel

- 7 M

- ISI Certified

- Upto 35 Mtr

- 2 HP

- Horizontal

- Upto 35 Kg/cm2

- 15 LPM

- Self Priming

- 1/2 inch BSP

- Standard

- Less than 75 dB db

- Upto 35 Kg/cm2

- Other

- Manual

- Nitrile Rubber

- Manual

- Hydrostatic Pressure

- 50 Hz Hertz (HZ)

- Plunger Type

- Other

- 65 Celsius (oC)

- Portable, Easy to Operate

- Trolley Mounted

- 415 Volt (v)

- Electric

- 1440 RPM RPM

Hydrostatic Test Pump Trade Information

- Ahmedabad , Mumbai , Mundra

- Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 7 Days

- No

- We will do packing of this hydro test pump in standard wooden box packing as per customer requirement

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa, Middle East

- Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tripura, Pondicherry, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Tamil Nadu, Telangana, Uttar Pradesh, All India, South India, Central India, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Uttarakhand, West Bengal

- WE ARE ISO CERTIFICATE

Product Description

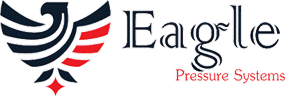

500 BAR Hydro Test Pump is consist of PXI 21.50 series Triplex Plunger Pump. Eagle Pressure Systems Vatva, Ahmedabad based Company are Manufacturers of Electric Hydrostatic Test Pump 500 bar as per above technical specifications as per customer needs.

Technical Specification:

- Type: Triplex Style Plunger Pumps

- Flow Rate: 21 LPM

- Min. Pressure: 350 BAR (5076 PSI)

- Max. Pressure: 500 BAR (7250 PSI)

- Motor (HP): 20 HP30 HP

Eagle Pressure Systems offers a wide range of hydrostatic test pumps. With field proven dependability in applications around the globe, Eagle Pressure Systems provides the best value for High Pressure Hydrostatic test pumps and systems.

Electric Hydro Test Pump Features:

- Direct Drive, very easy to use

- Silent noises free Electric Operated Motorized Pump

- Triplex Plunger Type

- Compact design

- Reliable and Efficient Performance

- Portable

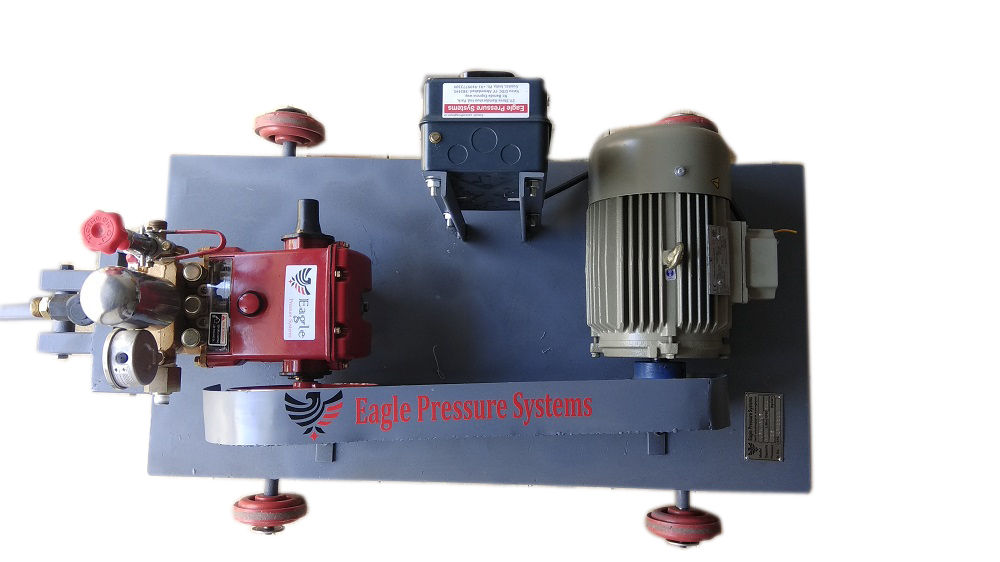

Product Details:

|

Pressure |

Max. 750 Bar |

|

Brand |

Eagle |

|

Usage/Application |

jet cleaning cum tubes cleaning |

|

Automation Grade |

Semi-Automatic |

|

Working Pressure |

Max. 750 Bar |

|

Power |

UP to 100 HP |

|

Voltage |

3 Phase , 415 V |

|

Flow |

Max. 70 LPM |

|

Power Source |

Electric / Diesel engine |

|

Flow Rate |

Up to 70 LPM |

|

Condition |

New |

|

Phase |

Three Phase |

|

No. Of Phases |

3 Phase |

|

Driven Type Available |

Directed Coupled OR Belt Pulley driven |

|

Mounting Option |

Four Wheel Trolley Mounted |

|

Is It Portable |

Portable |

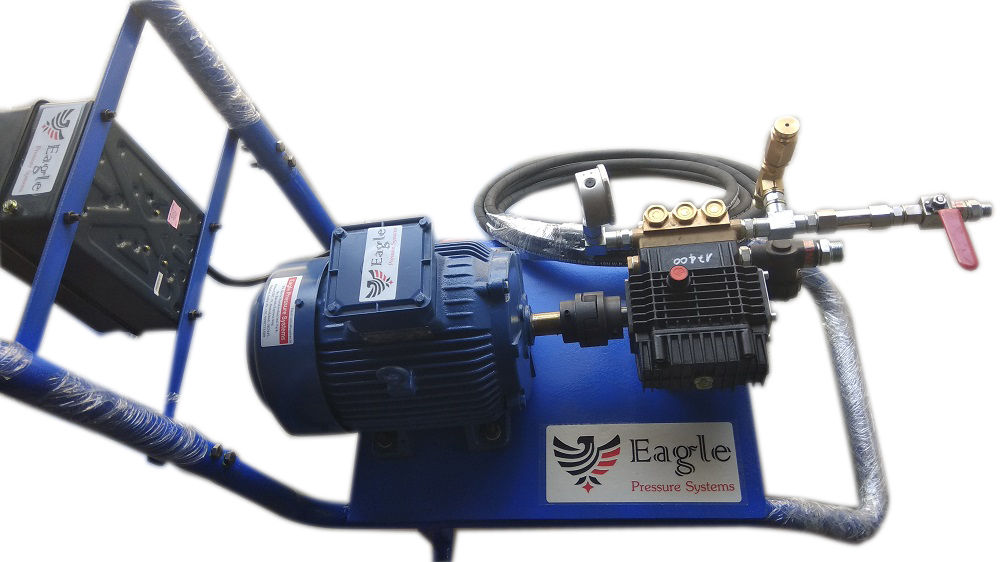

Reliable Pressure Testing Solution

Engineered for precision and reliability, this Hydrostatic Test Pump is ideal for rigorous pressure testing tasks. Its horizontal structure, efficient coolant system, and sturdy trolley design ensure easy mobility and operational stability. Suitable for use in various environments, it meets ISI standards for safety and performance, making it a trusted choice among distributors, exporters, manufacturers, and suppliers in India.

User-Friendly Design & Versatility

The pump features manual priming and control, offering straightforward operation for routine and specialized testing. With a five-meter hose, nitrile rubber seals, and 1/2 inch BSP inlet/outlet, it accommodates a variety of test setups, using water or oil as the medium. Its compact dimensions enable convenient transport and storage, while self-priming capabilities allow reliable suction up to seven meters.

FAQs of Hydrostatic Test Pump:

Q: How does the Hydrostatic Test Pump operate during pressure testing?

A: The pump utilizes a three-phase induction motor to draw the testing medium (water or oil) through its self-priming mechanism. Pressure is manually controlled and monitored, while an integrated safety valve automatically relieves any overpressure during operation.Q: What applications is this hydrostatic test pump suitable for?

A: This pump is specifically designed for pressure testing in plumbing, gas, and hydro systems, making it suitable for verifying the integrity of valves, pipes, and cylinders in both commercial and industrial settings.Q: When should I use water or oil as the testing medium?

A: The choice between water and oil depends on the system and component being tested. Generally, water is used for standard plumbing and hydro systems, while oil may be preferred when water is incompatible with the material or system requirements.Q: Where can this pump be installed and used effectively?

A: Thanks to its portable trolley-mounted frame and compact size (650 x 370 x 540 mm), you can deploy this pump in workshops, construction sites, industrial facilities, and field operations across different locations.Q: What is the process for setting up and priming this pump?

A: Simply mount the pump on a stable surface, attach the five-meter hose to the inlet and outlet (1/2 inch BSP), fill with the chosen medium, and manually prime before initiating pressure testing. The control system allows you to adjust and monitor pressure throughout the process.Q: How does using this hydrostatic test pump benefit my operation?

A: It delivers accurate and safe pressure testing, enhances operational efficiency with its portable design, ensures compliance with ISI standards, and prevents system failures through reliable overpressure protection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese